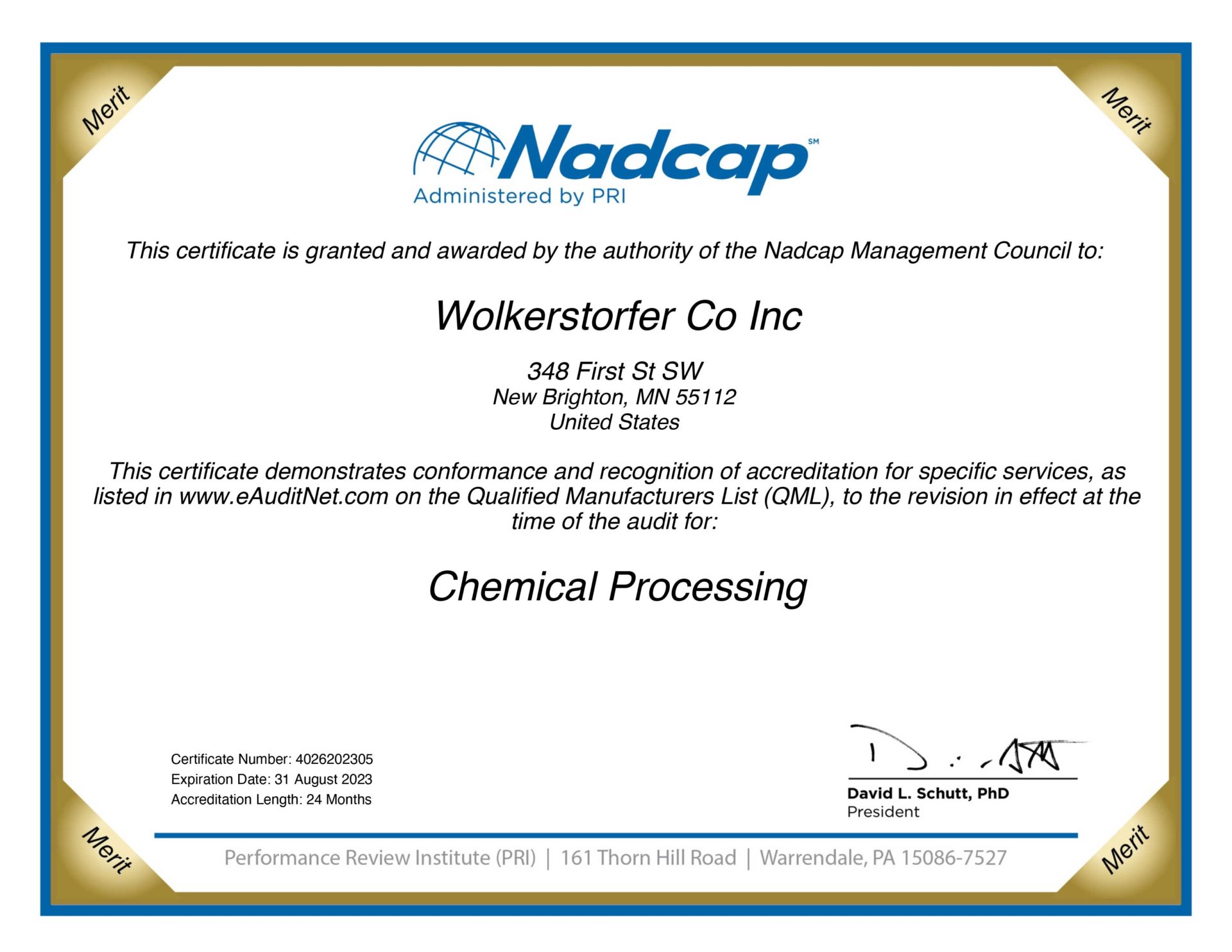

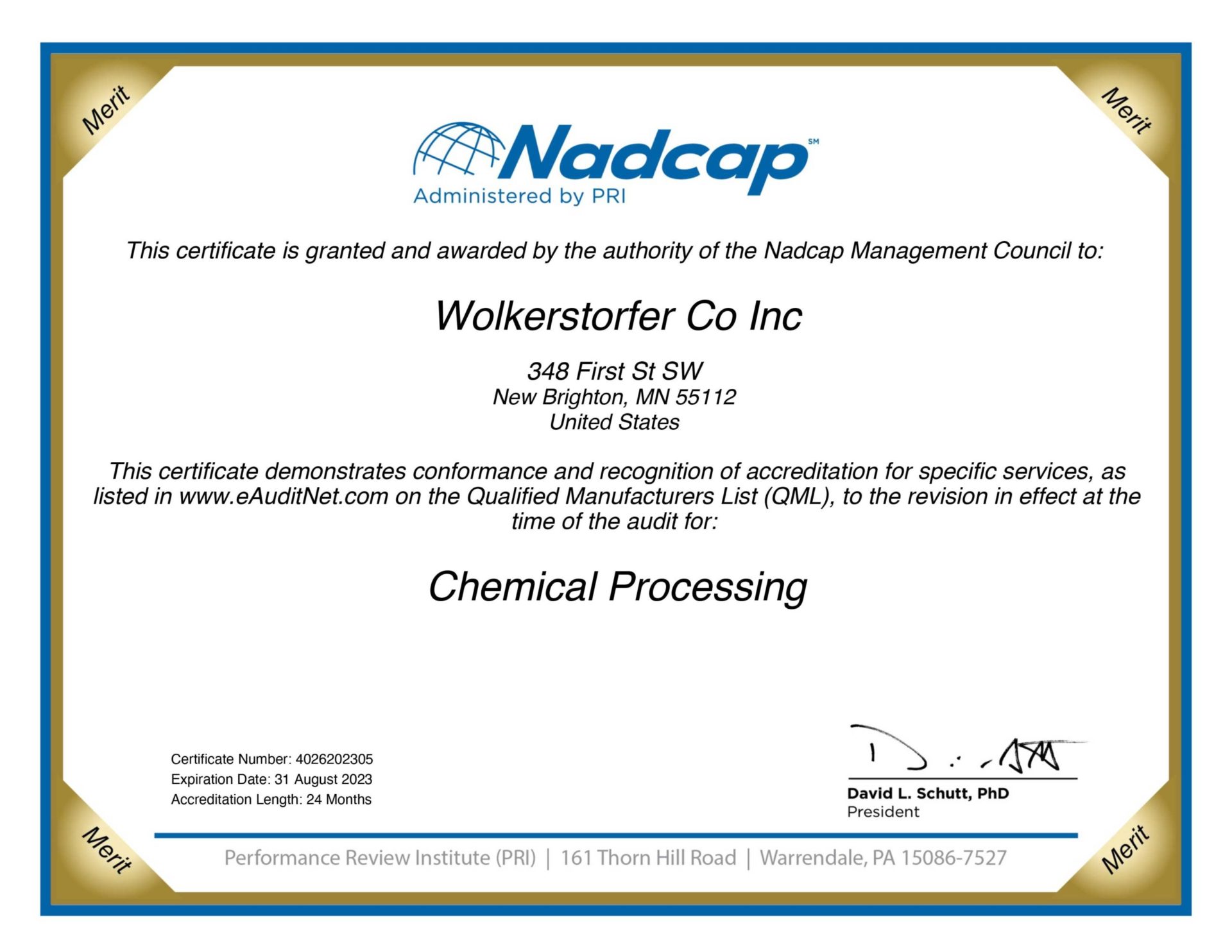

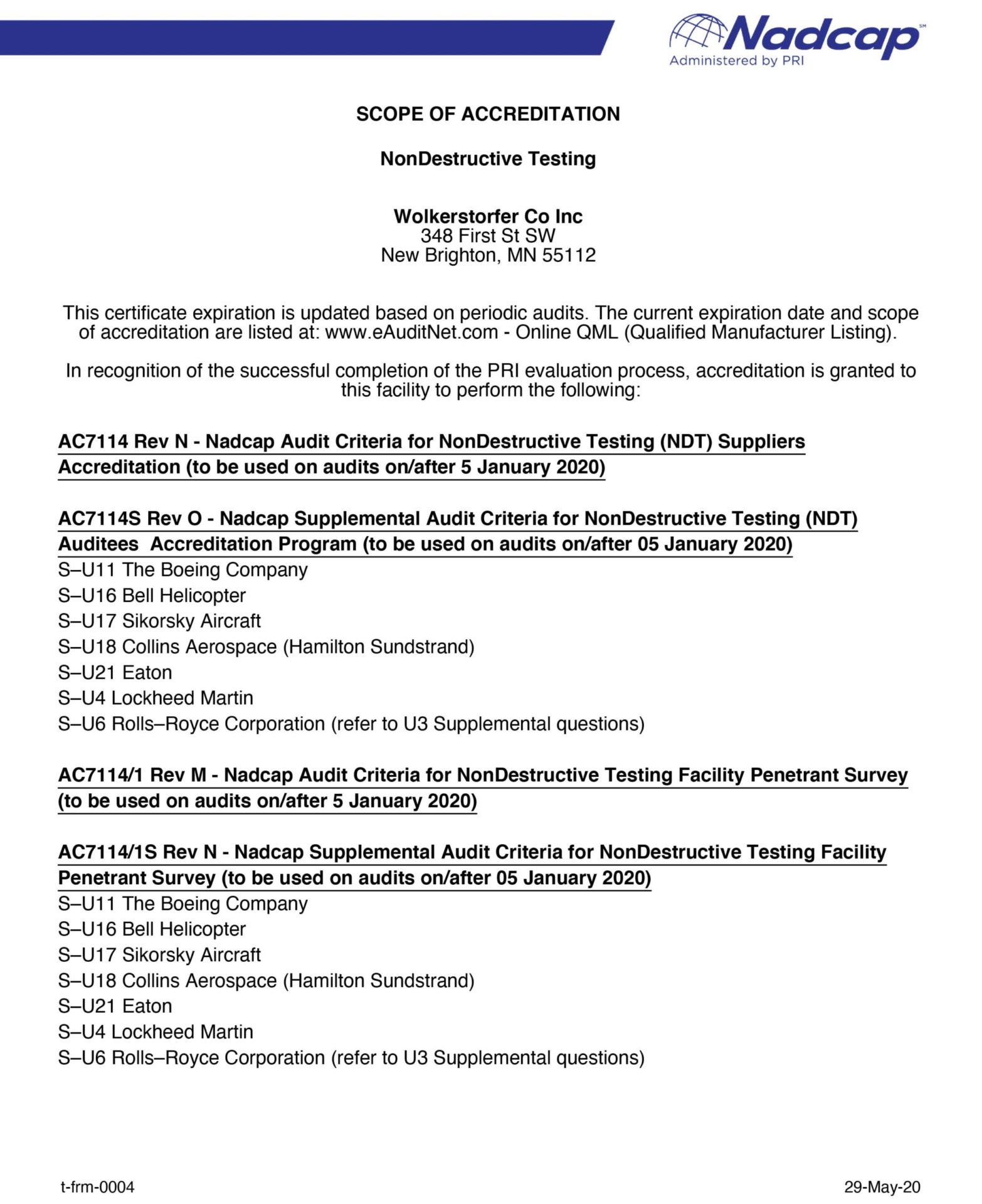

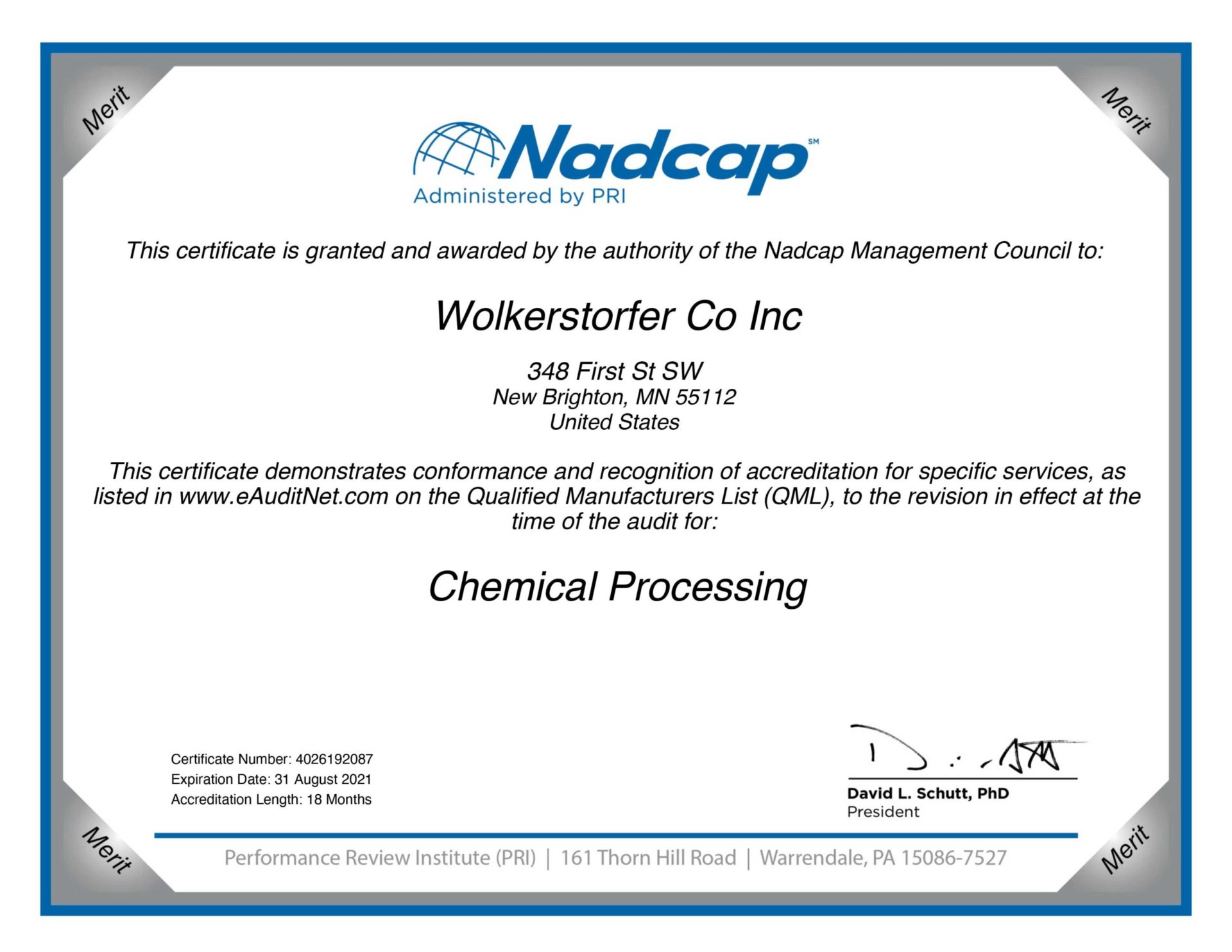

Nadcap Certified Passivation – Nitric and Citric

Now Nadcap certified for nitric and citric passivation of stainless steel.

The passivation of stainless steel is a procedure that enhances the protective characteristics inherent in all stainless steel alloys. During the manufacturing process, contaminants in the form of free iron and sulfur will be brought to the surface from turning, grinding, and milling. To remove these contaminants, without attacking the parent metal, a metal finisher will immerse the parts in a number of different solutions.

Stainless Steel Passivation Specifications

AMS2700

AMS QQ-P-35

ASTM A380

ASTM A967

BAC 5625 (Boeing)

QQ-P-35 (superseded by AMS2700)

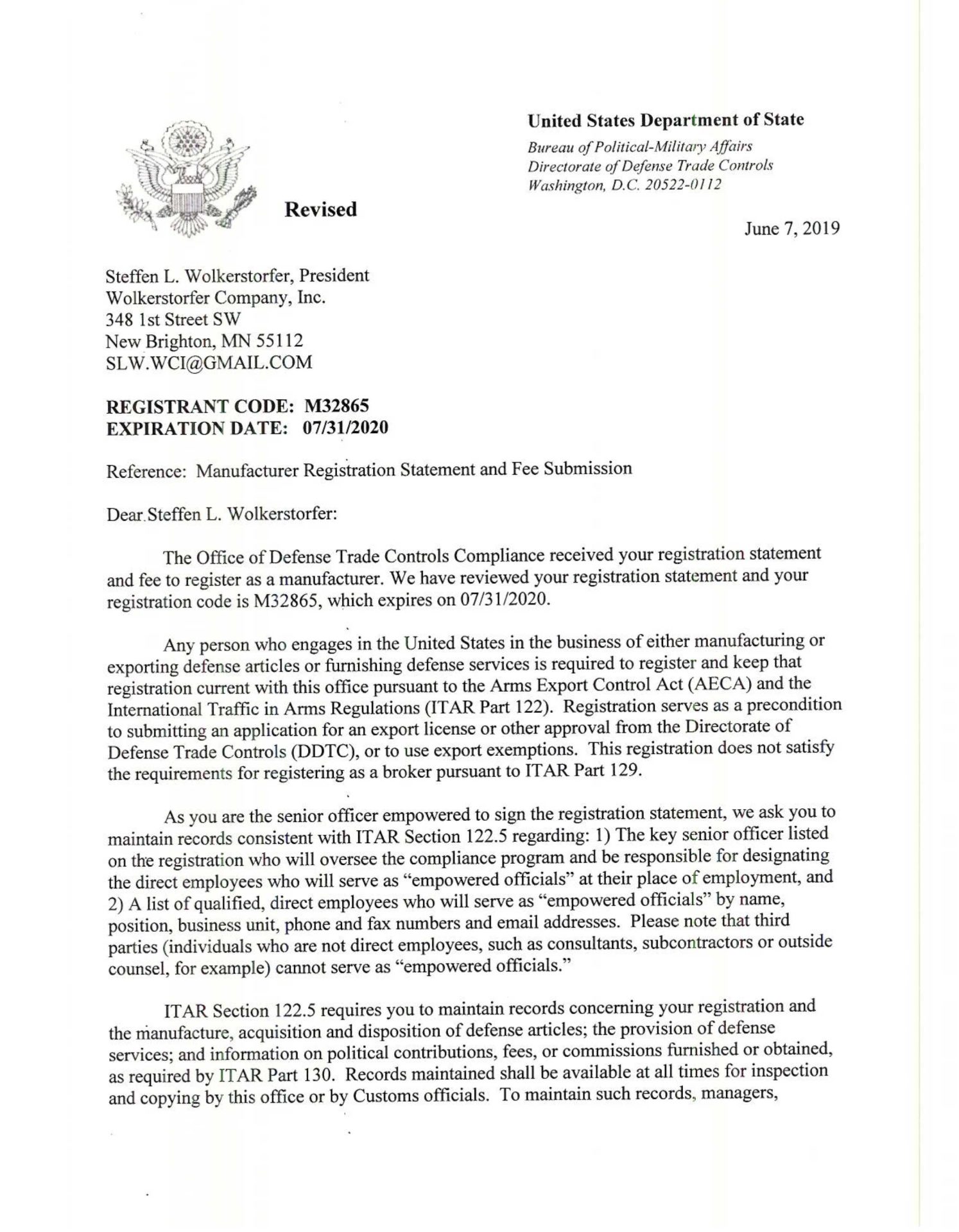

The passivation of stainless steel is a procedure that will enhance the protective characteristics inherent in all stainless steel alloys. During the manufacturing process, contaminants in the form of free iron and sulfur will be brought to the surface from turning, grinding, and milling. To remove these contaminants, without attacking the parent metal, a metal finisher will immerse the parts in a number of different solutions. Corrosion is always a problem, but when you are dealing with aerospace and defense work only a Nadcap certified metal finisher will do the job and do it to specification. As simple as it sounds the actual chemistry that is used is dictated by the alloy itself. 300 series stainless steel is not processed the same as 400 series stainless steel. There are some alloys that should not be passivated at all because of the potential of damage to the parts themselves. Carburized and nitrided parts, as well as 440C, should not be passivated. In the ASTM A967, there are 5 different concentrations, temperatures, and dwell times for both nitric and citric chemistries. After processing, there are up to eight different ways to test and validate the process. We offer Nadcap copper sulfate, water immersion, and salt spray post testing as determined by the specification and purchase order.

Depending on the specification we can process parts up to 30 feet in length and 2,000 pounds. For all of these reasons, Wolkerstorfer Company is the best choice when it comes to your Nadcap Passivation requirements.

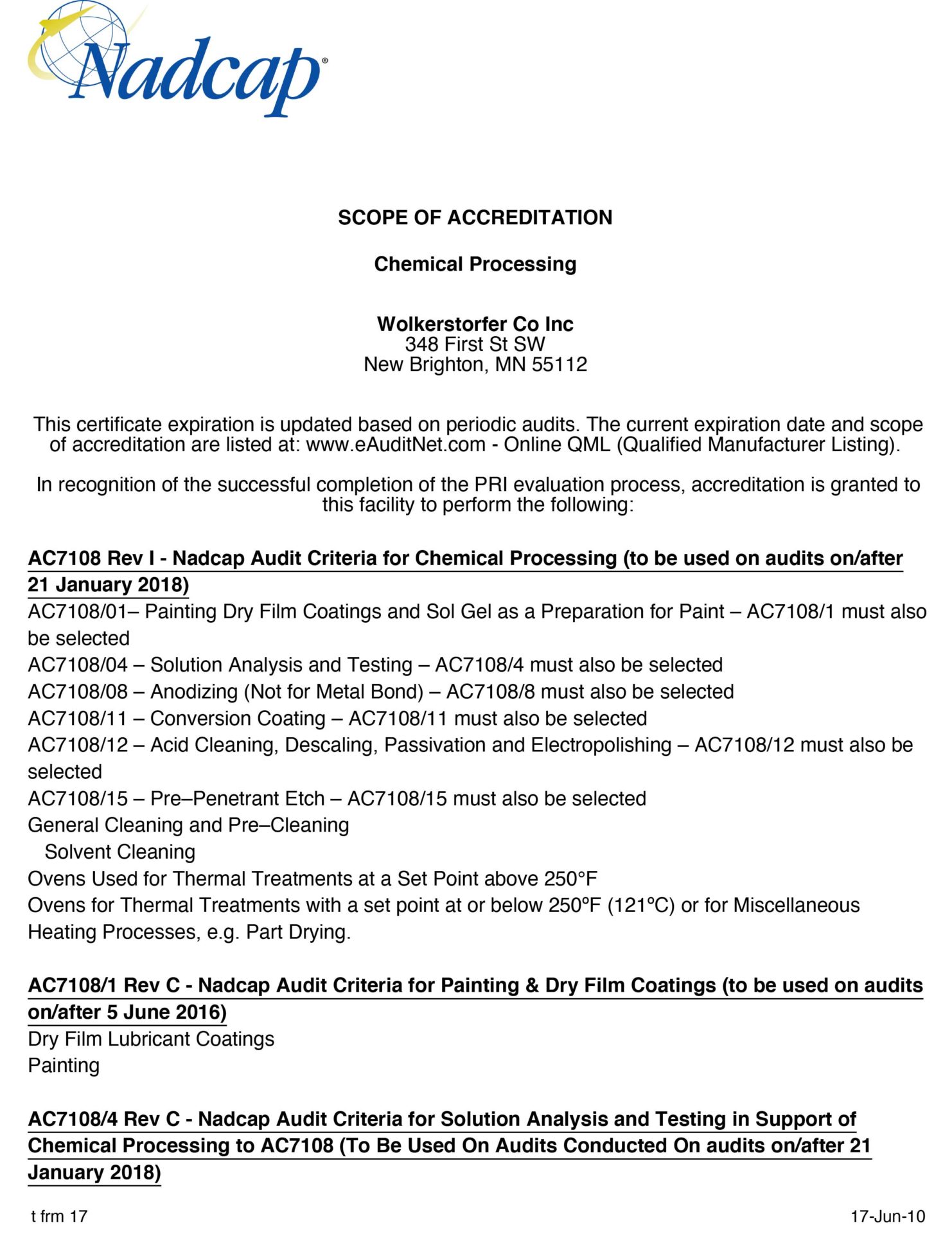

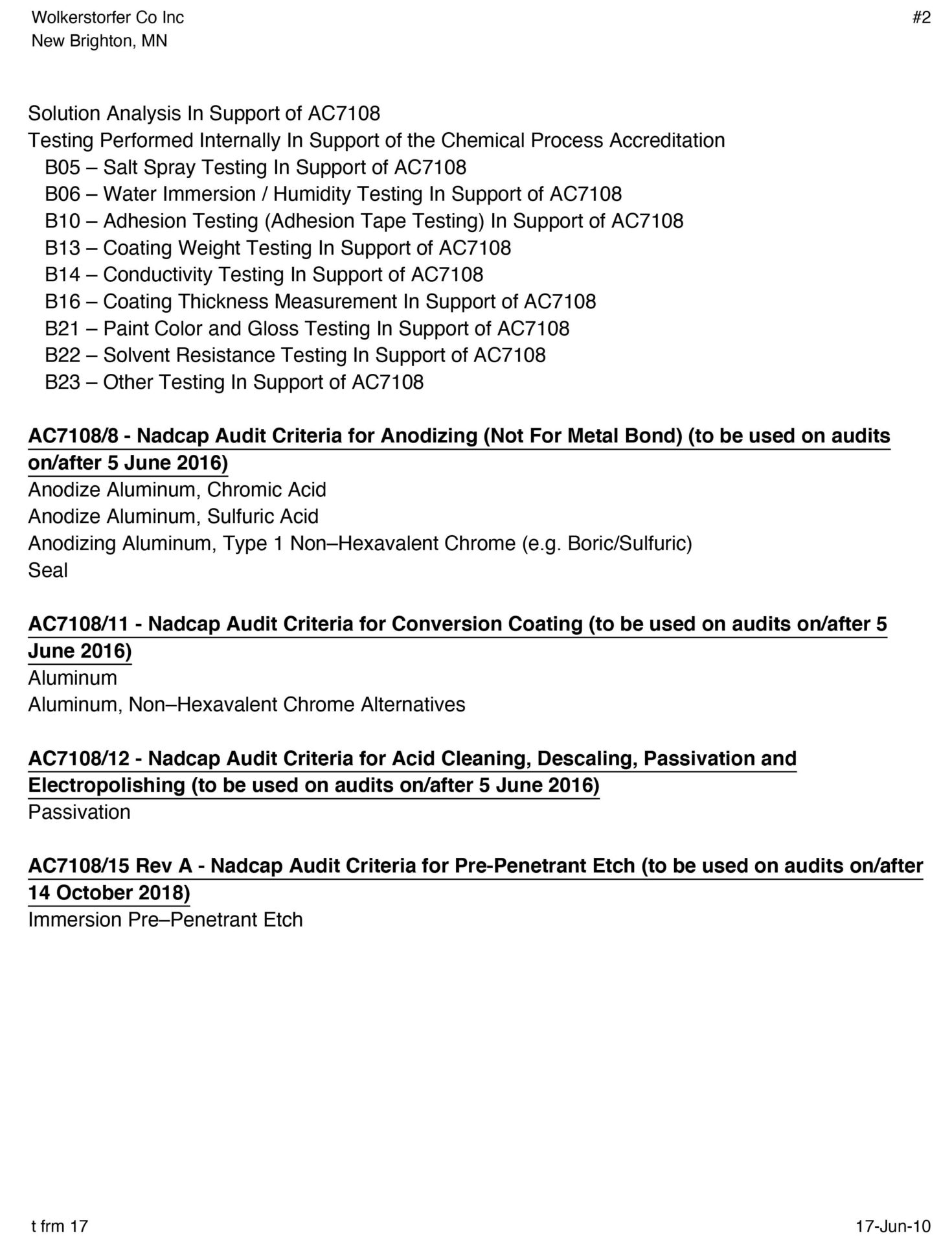

Click here to view a copy of our Nadcap Certifications.