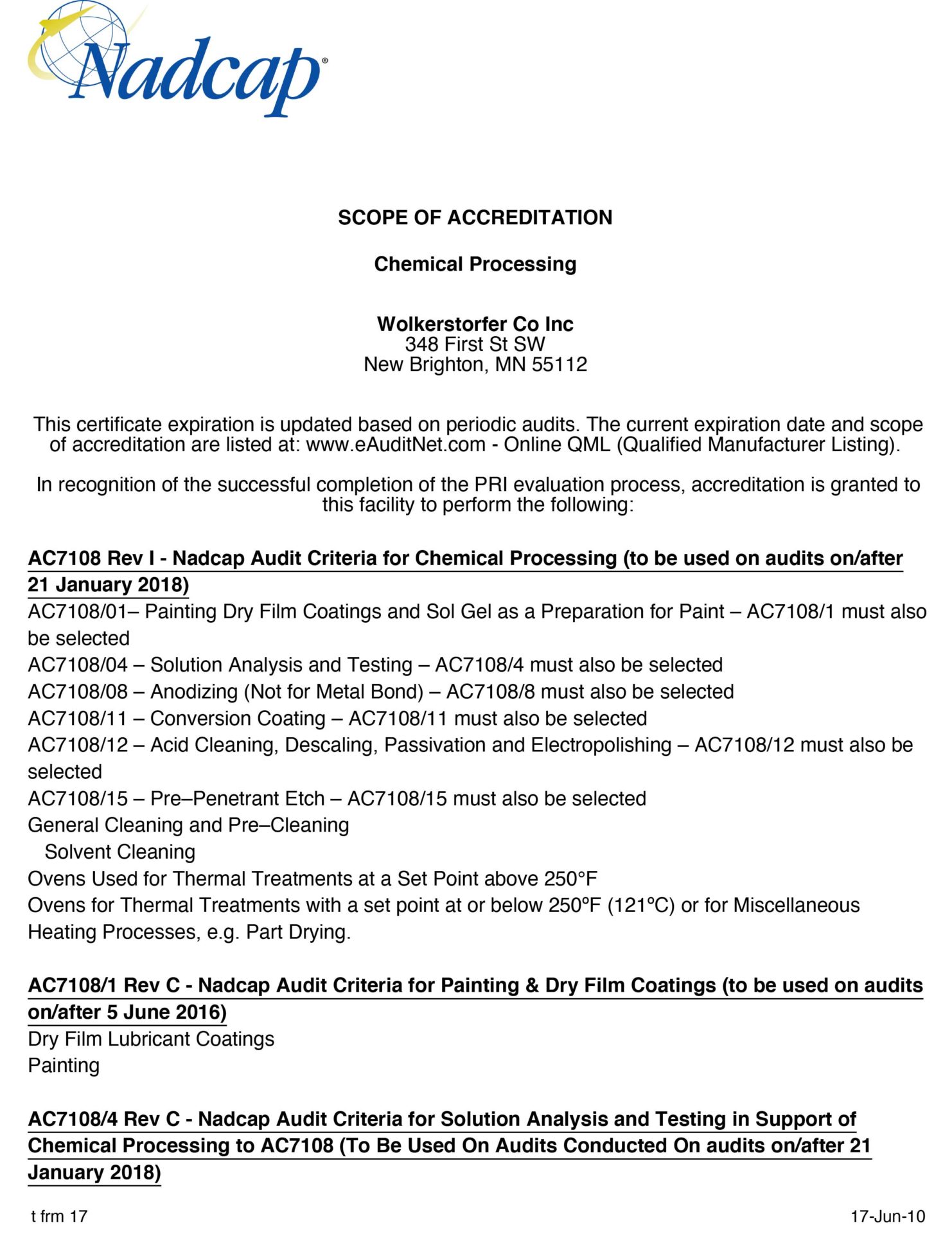

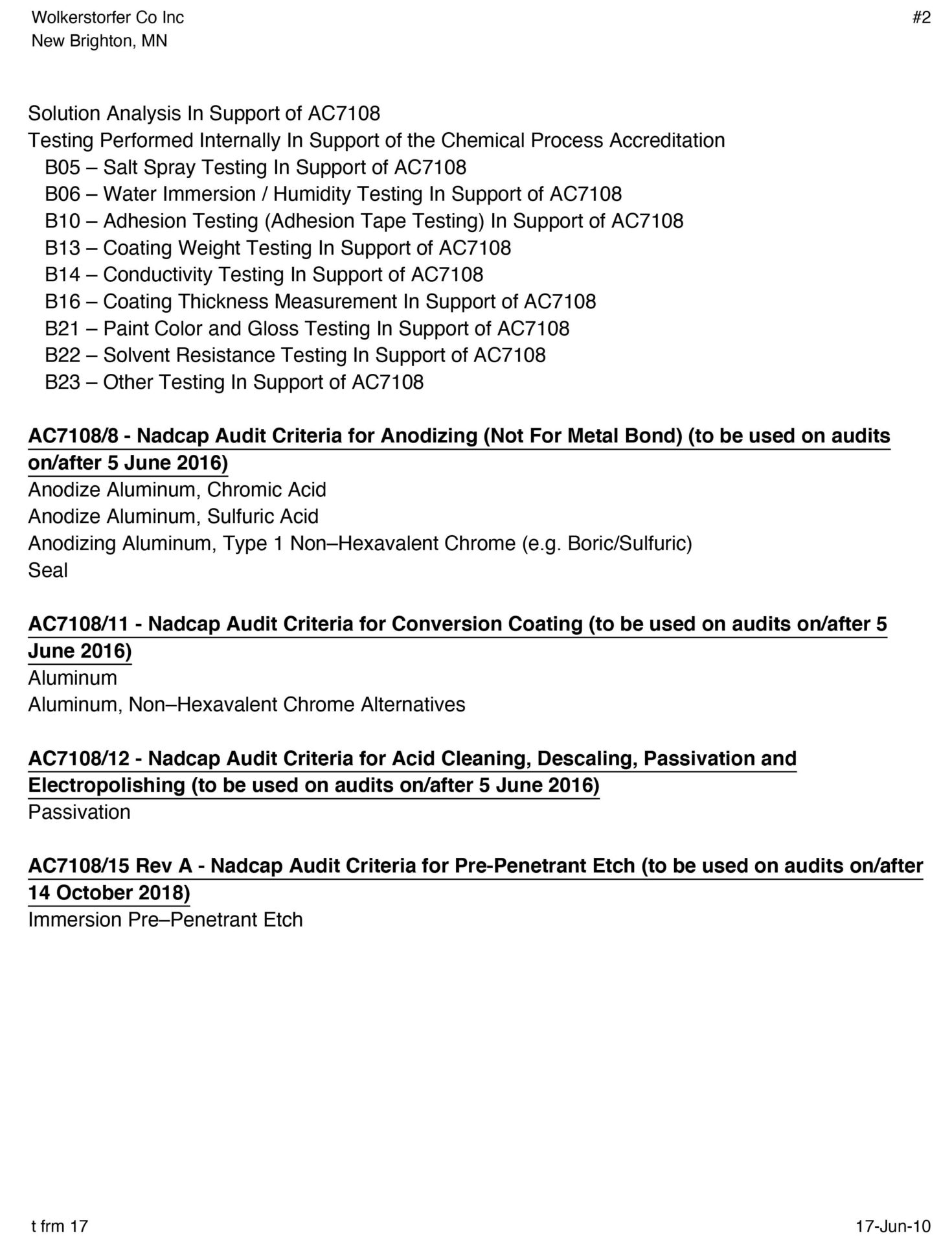

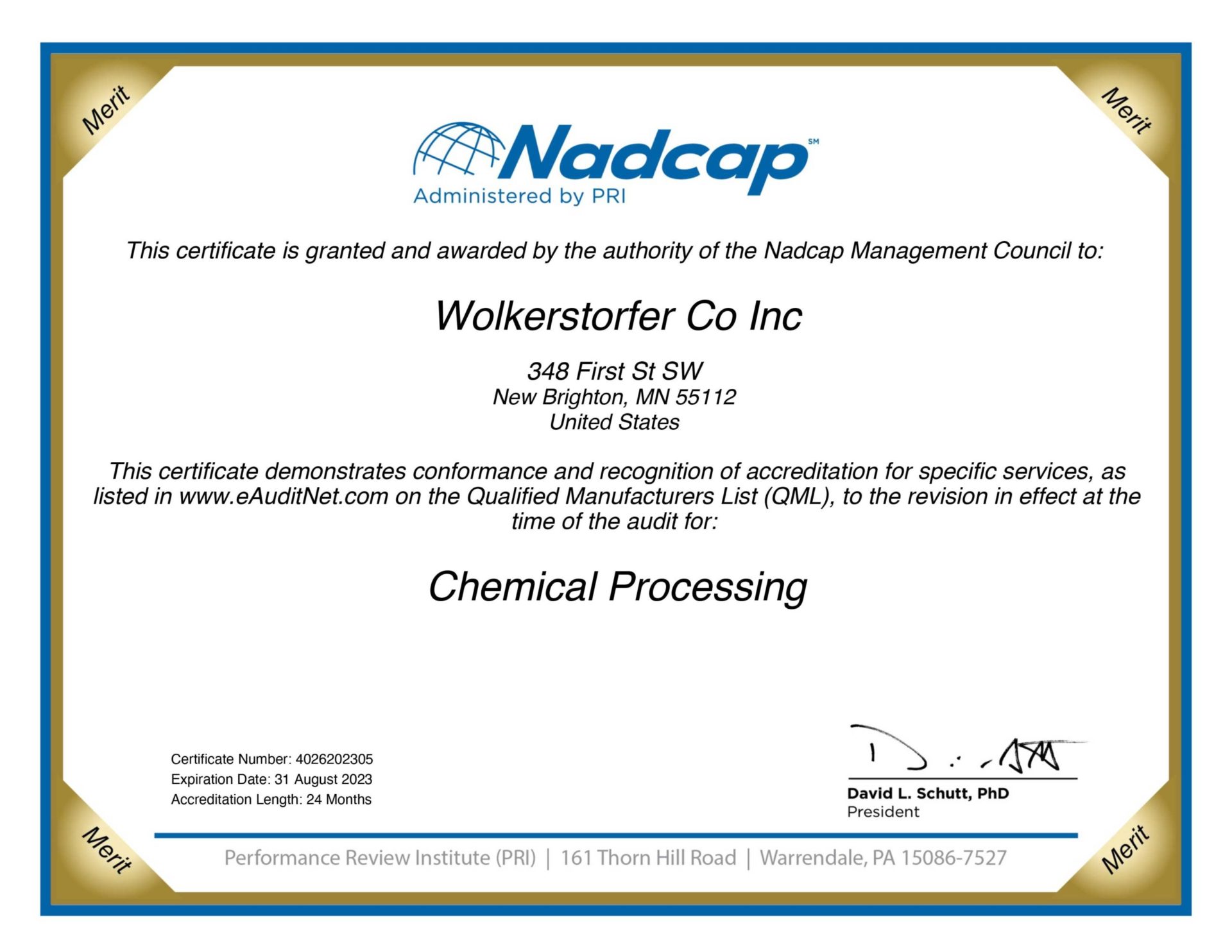

Nadcap Dry Film

MIL-L-23398 Lubricant, Solid Film, Air-Cured, NATO Code # S-749

MIL-PRF-46010 Lubricant, Solid Film, Heat Cured, NATO Code # S-1738

MIL-PRF-46147 Lubricant, Solid Film, Air Cured, Corrosion Inhibiting

MIL-PRF-81329 Lubricant, Solid Film, Extreme Environment NATO Code # S-137

SAE AS 1701 Lubricant, Solid Film

SAE AS 5272 Lubricant, Solid Film, Heat Cured

* Capabilities include but are not limited to the above.

The term Dry Film Lubricant (DFL) or Solid Film Lubricant (SFL) are generic terms for a coating that can be dipped, sprayed, or brushed on the surface of a part in order to protect it from wear and/ or corrosion. These broad terms cover a number of different coatings, but we will focus on two materials, namely molybdenum disulfide (MoS2) and polytetrafluoroethylene (PTFE), also known by its trade name Teflon®.

Wear Protection

In engineering terms, the science of wear, friction, and lubrication is called Tribology. In the early days, animal-based soaps and waxes were used, as well as crude oils and greases. To that point, they are still used today, but there are other options to meet today’s demanding conditions that are much more practical and reliable.

Wet Film Lubricant vs Dry Film Lubricant

The main difference between a wet film lubricant and a dry film lubricant is largely how well they perform under heat and pressure. Because of this, it is important to understand the proper type of lubricant to use for a specific project so as to avoid issues or even failure.

A wet film lubricant will break down under high heat and literally be “squeezed out” under higher loads. A classic example would be a chain and a gear application where a chain drives the action. This naturally creates friction that, unless properly lubricated, will lead to stress and eventual failure. One example where this holds true is in aeronautics, where the “g force” will lead to the displacement of wet lubricant due to the physical dynamics.

Comparatively, a dry film lubricant, or solid film lubricant, will stay in place where the chain and gear make contact. The characteristics of PTFE coatings that distinguish them as dry-film lubricants include their high bond strength, extremely low coefficient of friction, and exceptional chemical resistance. With the ability to withstand the ingress of other chemicals, and high bond strength, dry film lubricants make for a solid solution in many applications.

Wear is the factor that, perhaps above all, requires the most attention. When measuring wear, in particular the sliding wear between two surfaces, the term that is used is the coefficient of friction, or µ (the Greek letter mu). The lower the number, the better the wear characteristics. In the case of two uncoated steel surfaces with kinetic wear, the measurement is around 0.50. When MoS2 or PTFE is used, values drop to around 0.05 to 0.20.

So how do you pick one over the other? PTFE works well with loads under 5,000 psi, temperature range of -400°F to +500°F, and low speeds. MoS2 works well with loads over 5,000 psi and can handle a temperature range of -400°F to +750°F with higher speeds.

Corrosion Protection

Another factor to consider when selecting a lubricant is corrosion resistance. Corrosion is caused by an electrochemical process. The majority or all of the atoms on a metal surface oxidize, which results in damage to the entire surface and causes general corrosion. The majority of metals are easily oxidized; they frequently lose electrons to oxygen and other elements in the atmosphere or in liquids. As oxygen is reduced (gains electrons), it joins with the metal to form an oxide.

The reason corrosion is such an important factor is the silent impact it can have on a much larger picture. For example, many factors affect the U.S. Gross Domestic Product or GDP. Oil prices, supply chain issues, and interest rates all have a role. One number that is not as well known is the cost of corrosion. Products that have a shortened life due to corrosion negatively affect the GDP by approximately 3% or hundreds of billions of dollars a year. Thanks to a greater amount of attention being paid to this issue, solutions such as improved alloys and surface treatments have had a major impact in recent decades in reducing that number. Modern dry film lubricant options are a primary reason for this advancement in performance.

Examples of Corrosion Protection

One of the many benefits of solid film lubricant coatings is that they provide a barrier coating against corrosion. In the early development of the MoS2, its first real commercial application was during the Vietnam war. Soldiers who were issued M-16 rifles found they would commonly jam or misfire, due to debris from the field that worked its way into the equipment, becoming trapped by wet lubricants. Standard “bluing” of the guns was replaced with a MoS2 coating, and it had immediate results. Not only did the dry film not attract grit, but it also proved superior corrosion protection.

A common way of measuring corrosion resistance is by testing per ASTM B117, Neutral Salt Spray Testing. This aggressive test is one way of benchmarking the performance of different coatings when compared to each other. For example, conventional zinc plating will hold for up to 48 hours before red rust appears, while electrolytic nickel will hardly exceed 96 hours. Depending on the product, some DFL systems will go over 400 hours, with some specialized systems capable of exceeding 3,000 hours.

Where Do You Go From Here?

So, what is the best choice when determining the right form of lubricant to use for your needs? In truth, every application is unique so there is not one product that will meet all your demands. The real question becomes whether or not you are seeing failure from your wet lubricant.

If you are finding that your wet film lubricant is leading to corrosion or wear, it may be wise to consider a dry film lubricant. With its broad application, the capability of being used on almost every type of substrate, and a thickness range of .0002″ to .001” per side, this versatile coating may be the perfect answer for your project.

To learn more about how we can help you achieve the best lubrication and protection for your needs, let our team discuss your project with you and help you find the right answer. Contact us today with any questions about our Nadcap dry film lubricant options and how they could work for you.