Why Nadcap Painting?

When OEMs and Tier 1 companies need to ensure protection and add eye appeal to their products, they often turn to paint. For the highest quality industrial painting that is demanded in the aerospace and defense industries, you need Nadcap Painting. Nadcap Painting is a quality standard that meets the strictest requirements and practices. At the Wolkerstorfer Company, we offer the highest level of Nadcap Painting that meets the requirements of Boeing, Lockheed Martin, and Raytheon, to name a few.

What Sets Nadcap Painting Apart?

When you think of the word “paint”, what immediately comes to mind? Perhaps you would think of the earliest times when cave dwellers decorated their walls, 40,000 years ago. Maybe you picture Michelangelo adorning the ceiling of the Sistine Chapel. Perhaps you imagine Picasso or the development of the Cubist style. Today, sadly, we may think of painting as no more than an unwanted chore around the house.

Here at Wolkerstorfer, “Paint”, has a more serious tone.

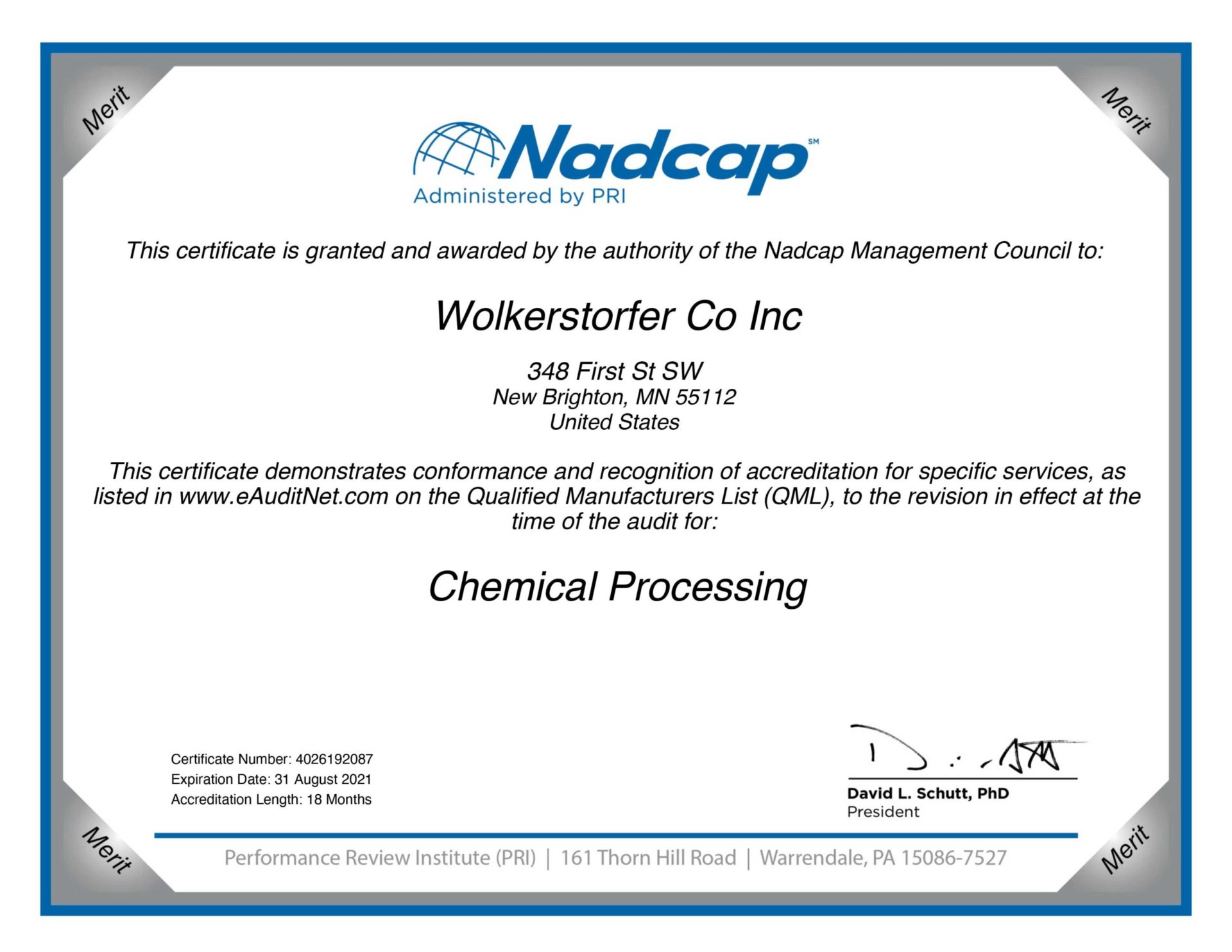

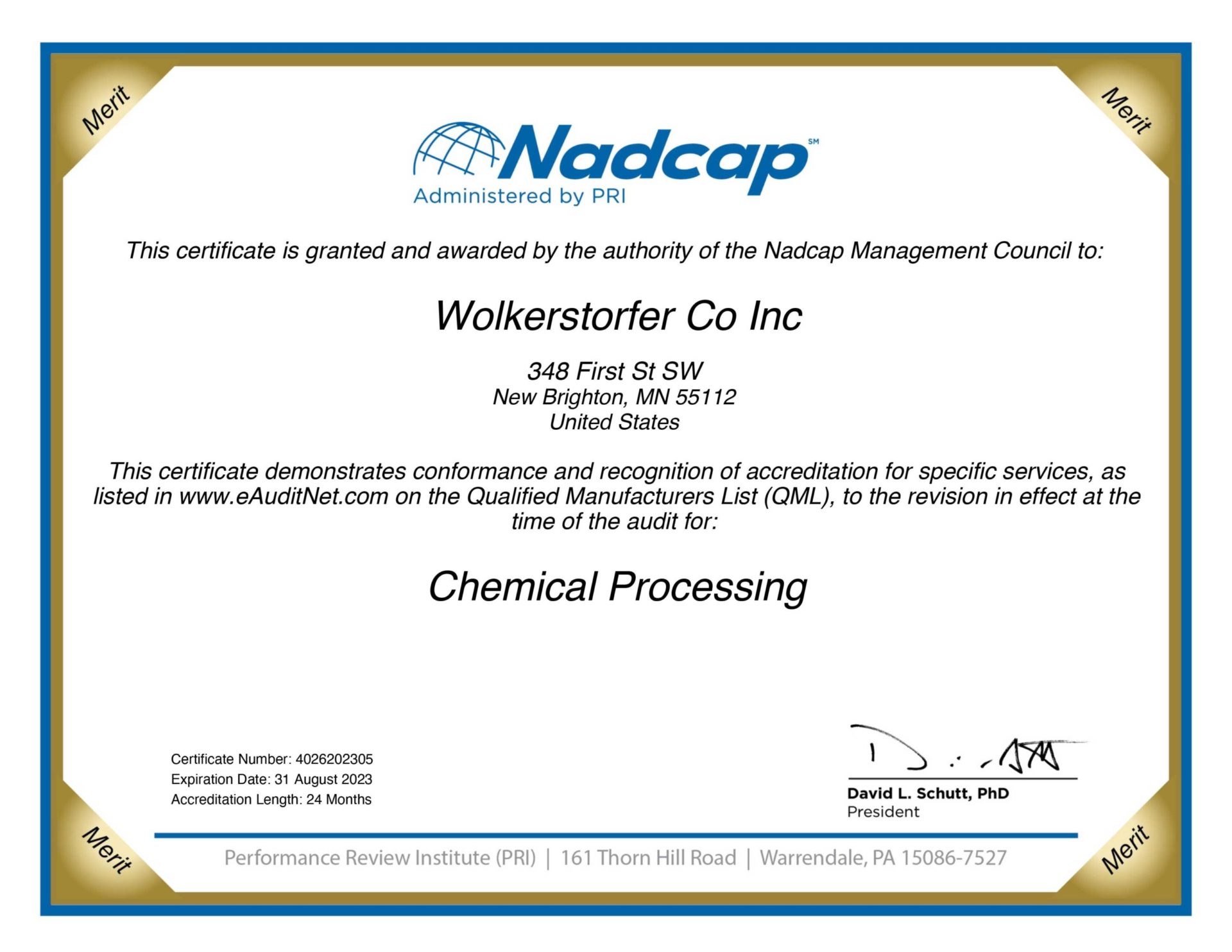

Wolkerstorfer is Nadcap Certified to apply Paint and Dry Films. We use various industrial painting systems to enhance the performance of aerospace and defense components. We work with coatings that provide improved lubricity, such as Dry Films or Chemical Agent Resistant Coatings (CARC) paints that protect our military. Wolkerstorfer Company is certified by numerous OEMs and Tier 1 suppliers because we have proven ourselves as a trusted Nadcap painting partner.

The key to optimizing these industrial painting systems is to follow discrete pretreatment steps, including cleaning, abrasive blasting, chem film, anodizing, phosphating, passivation, or detailed masking, before the first coat of paint is applied. The use of wash primers, primers, and sophisticated topcoat systems, per the OEMs specifications and the manufacturer’s instructions, ensure performance and durability.

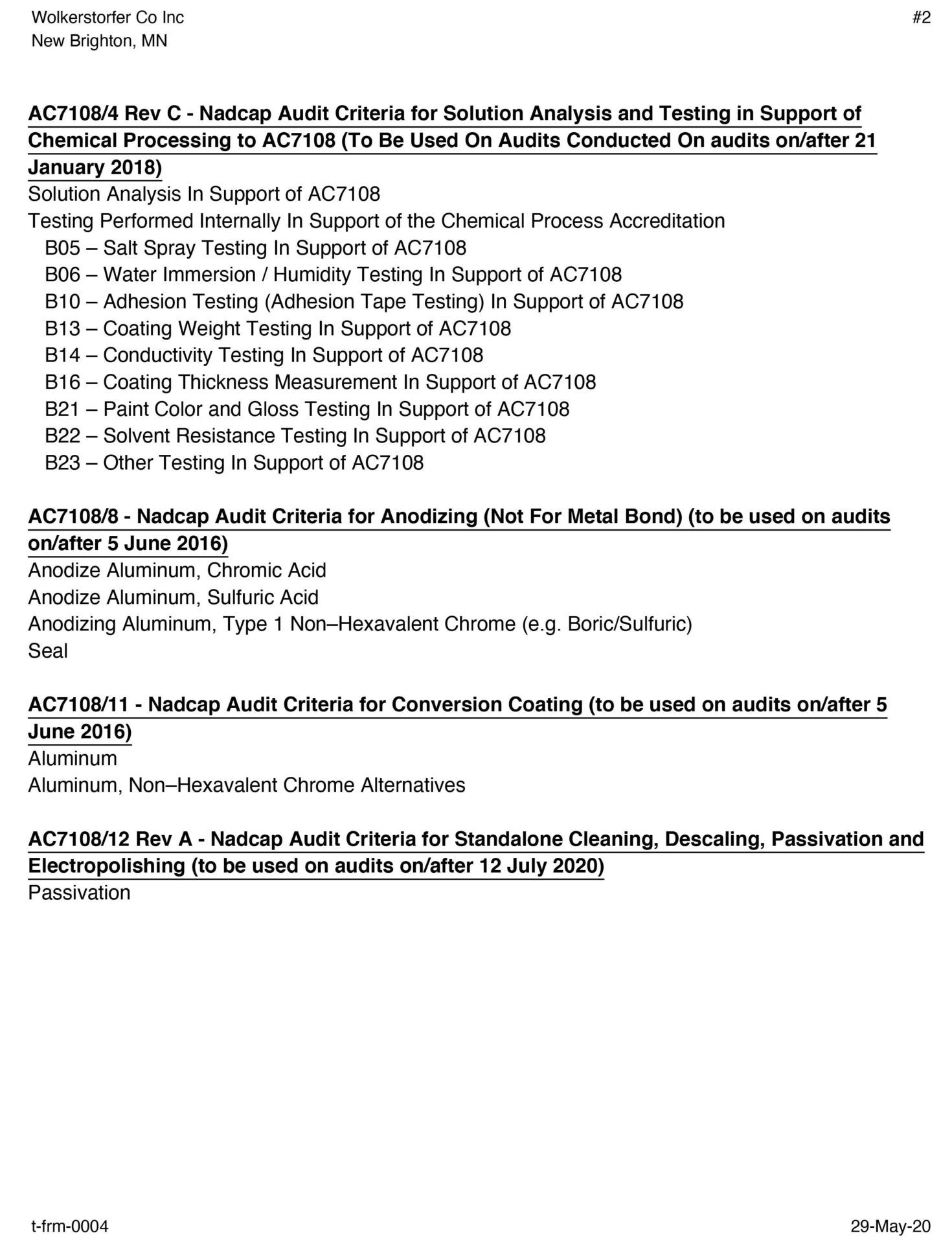

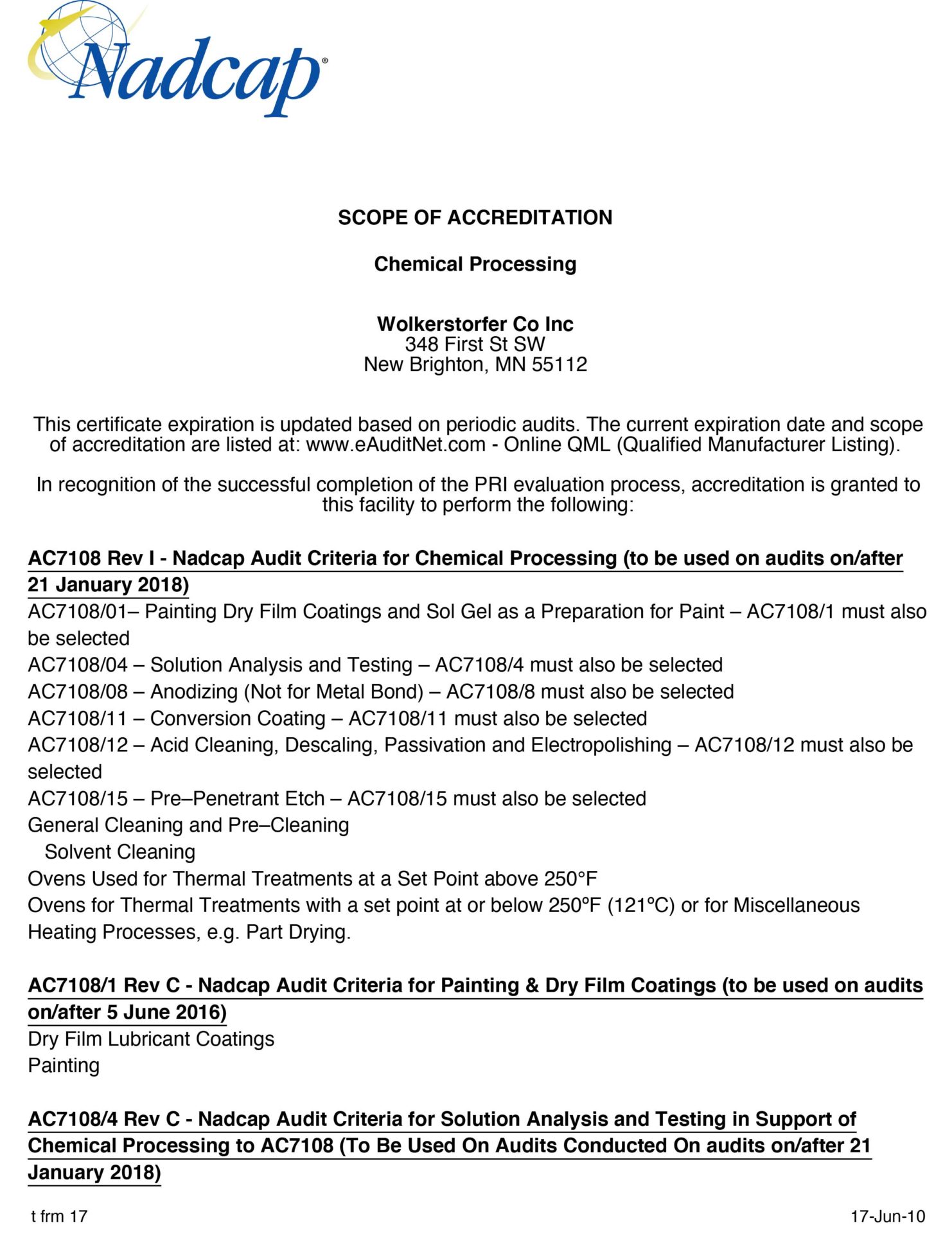

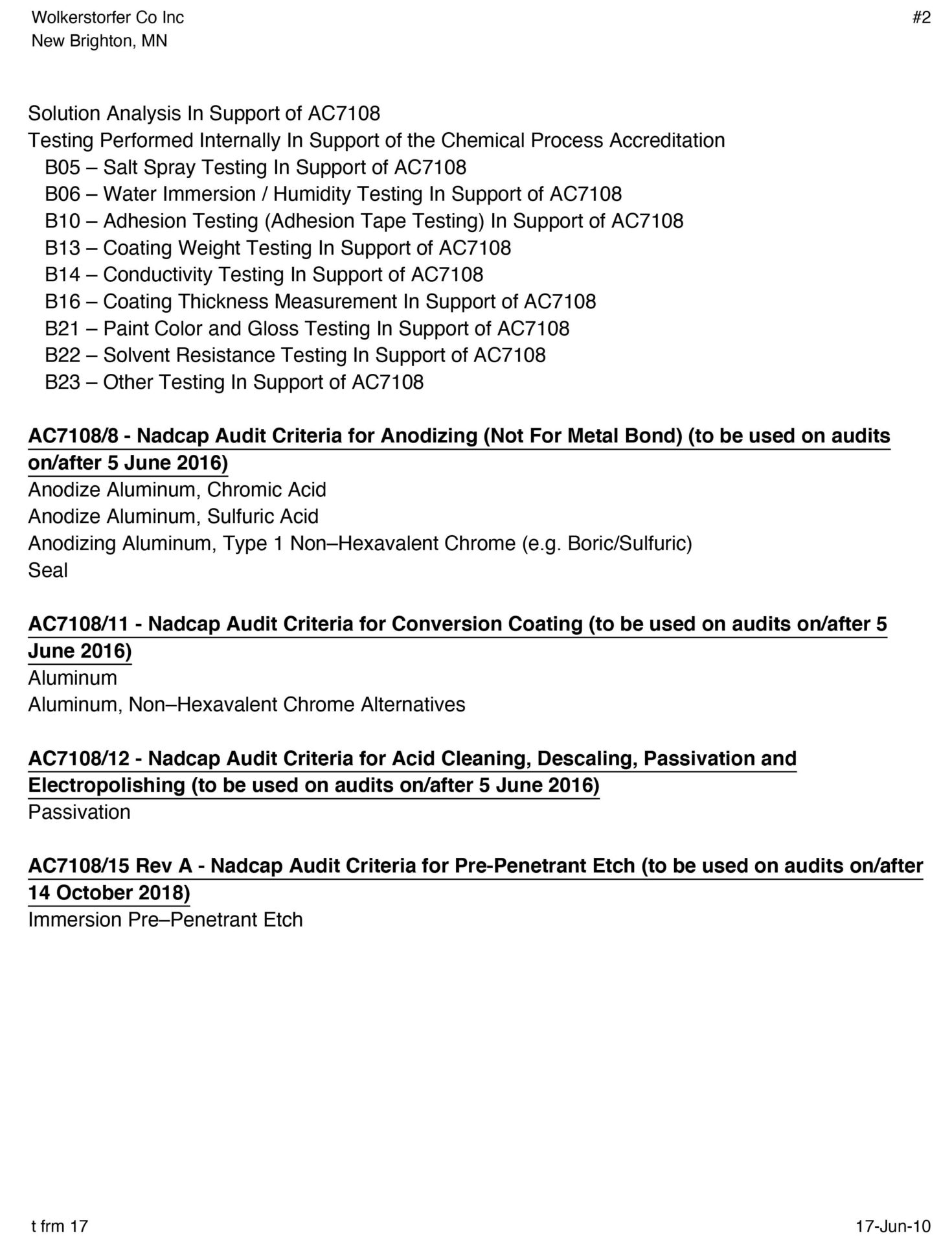

The primer, top coat, and dry film systems are Nadcap paint certified (AC7108/1).

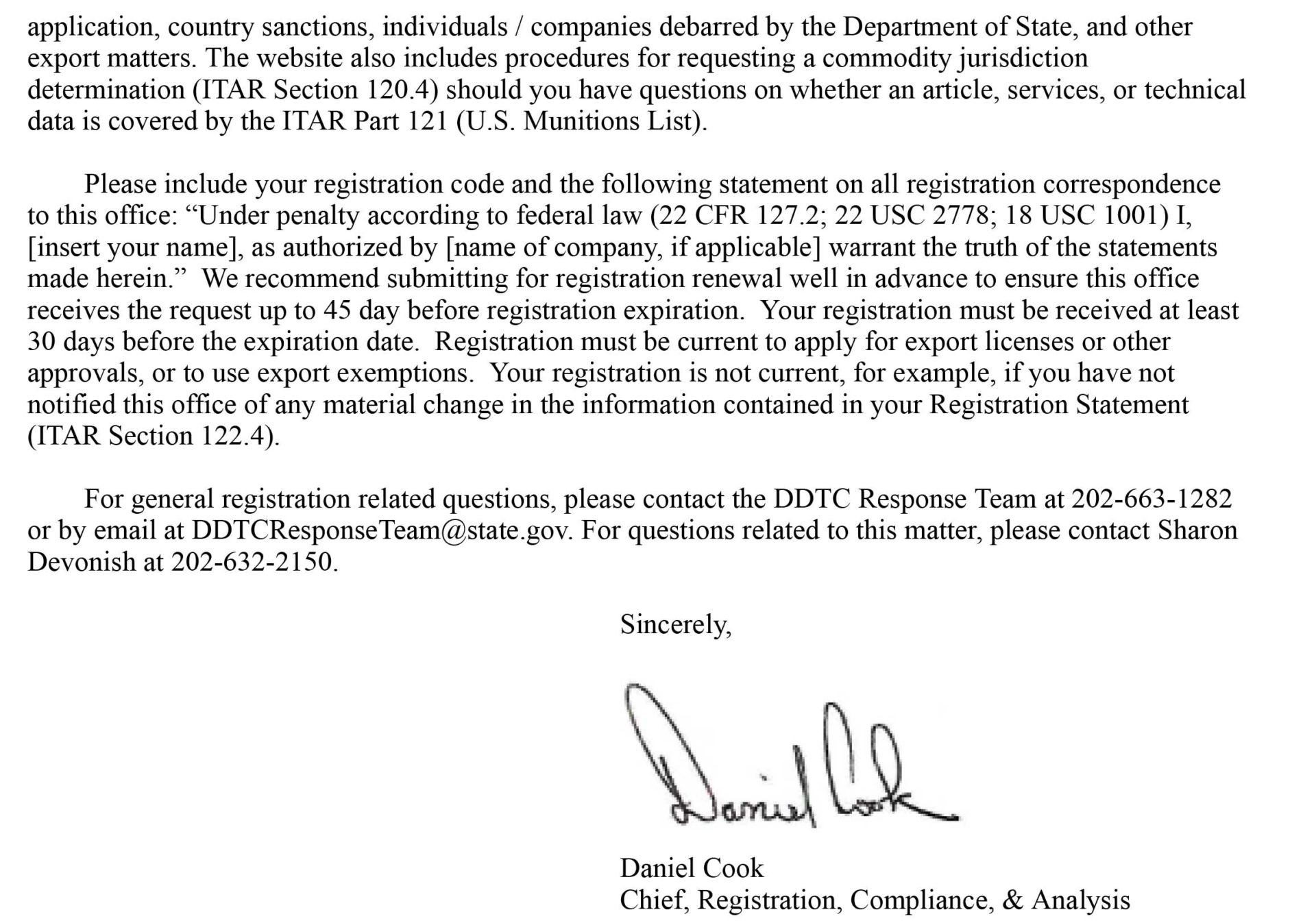

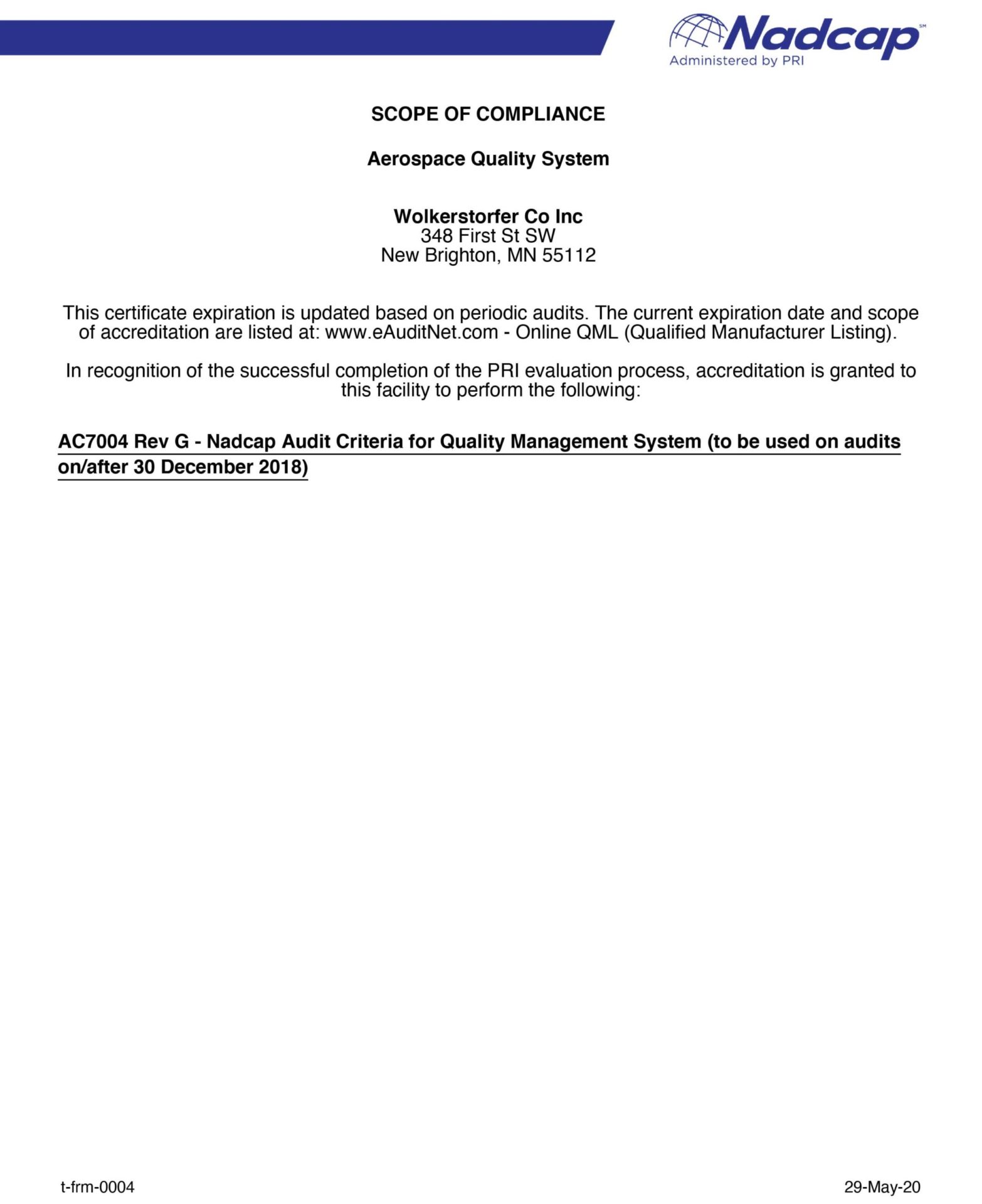

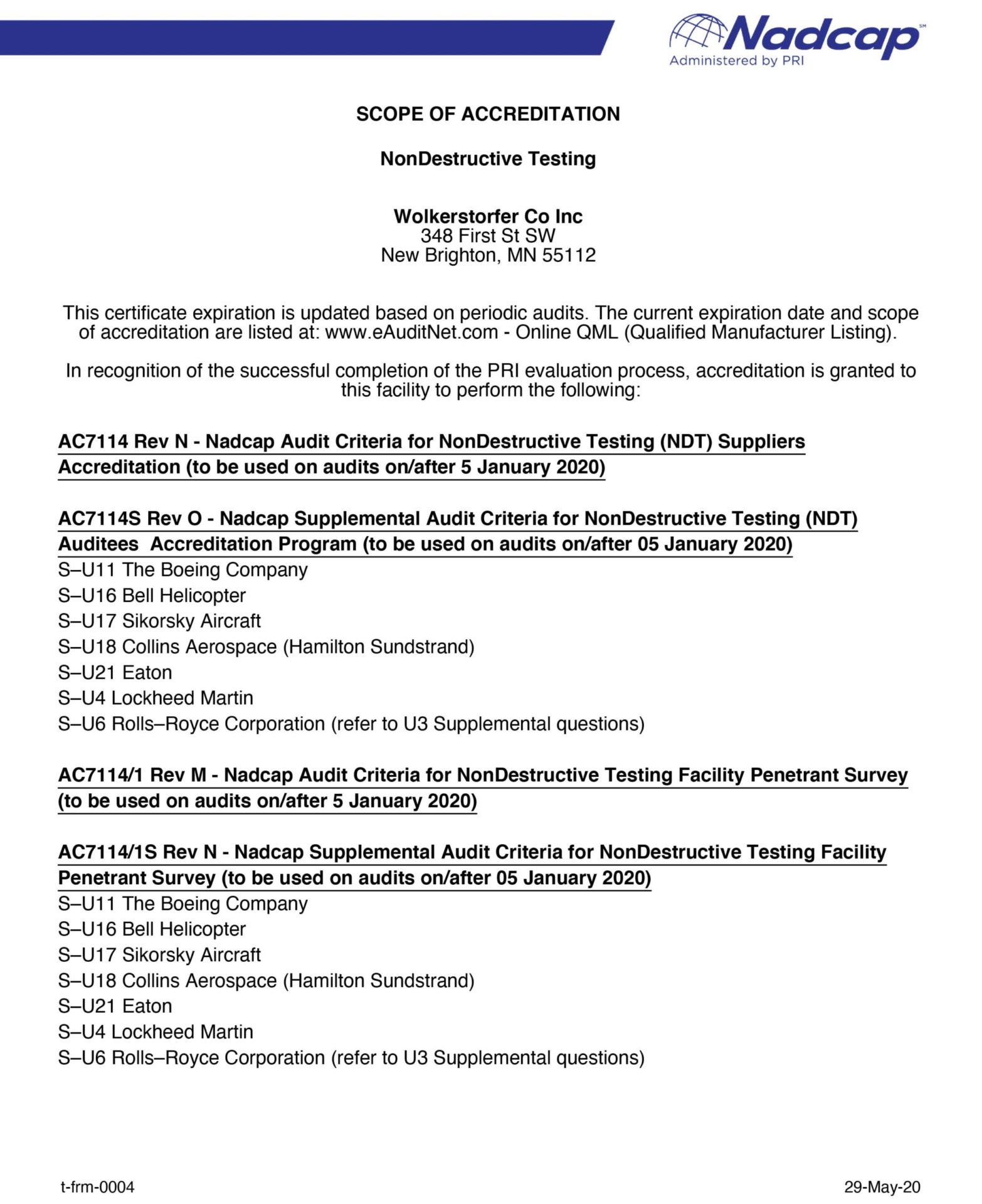

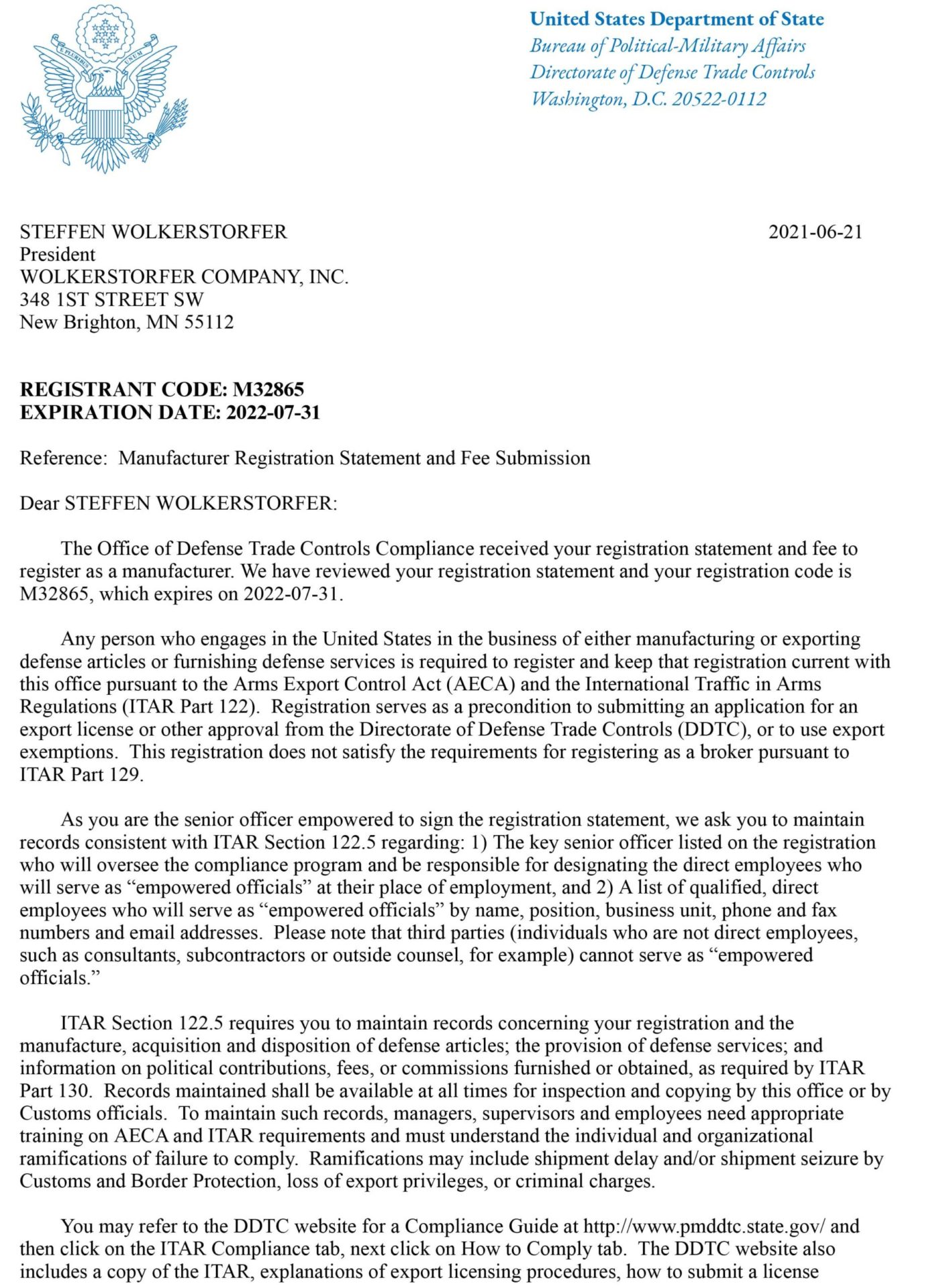

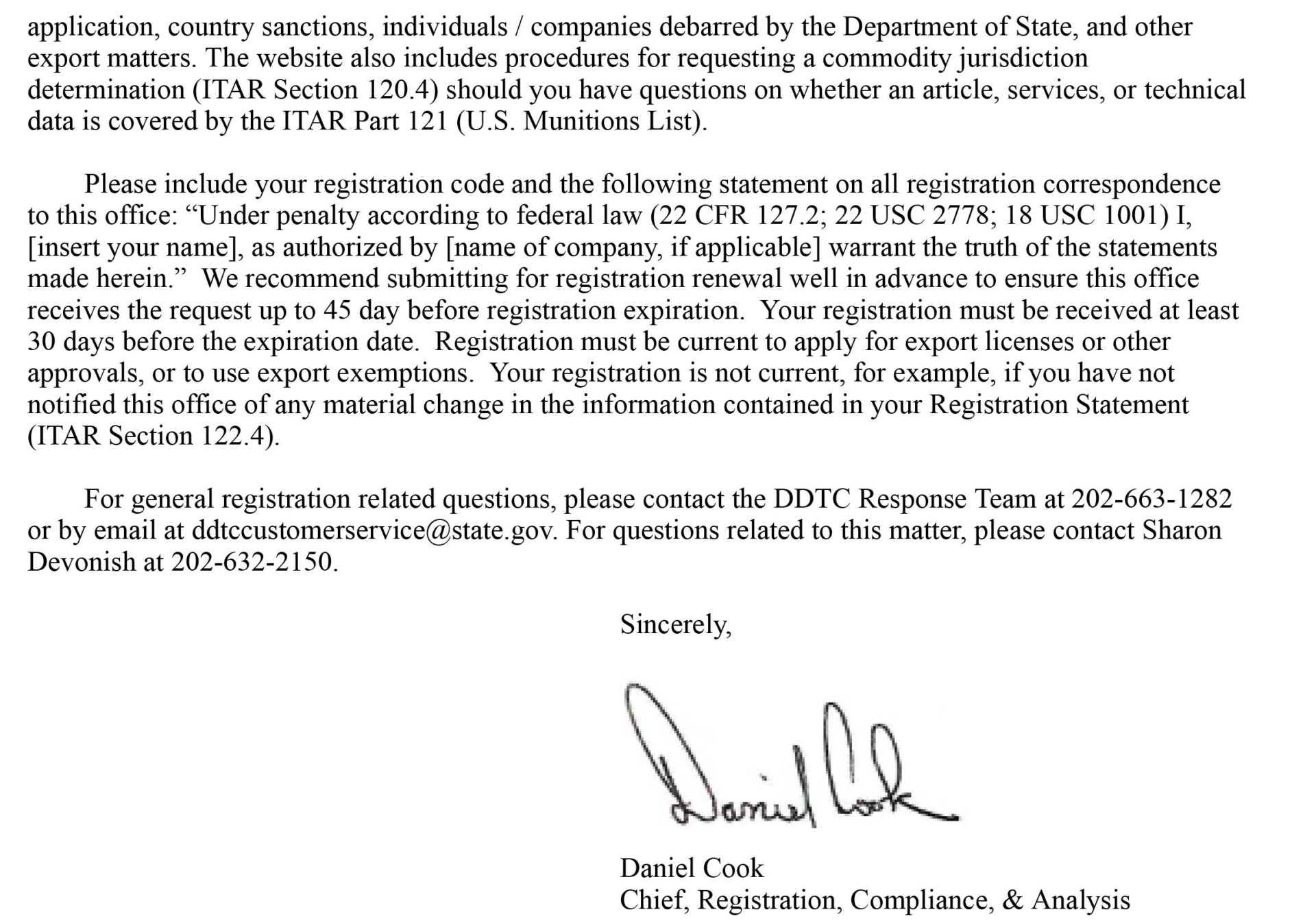

Click here to view our Nadcap Accredited / ITAR Registered Information.

For a summary of our paint booth and oven sizes click here

Why Trust Wolkerstorfer for Your Nadcap Painting?

The key to optimizing these systems is to follow discrete pretreatment steps including cleaning, abrasive blasting, chem film, anodizing, phosphating, passivation, or detailed masking before the first coat of paint is applied. The use of wash primers, primers, and sophisticated topcoat systems, per the OEMs specifications and the manufacturer’s instructions, ensure performance and durability.

Wolkerstorfer has been Painting, Plating, and Testing for more than 129 years. Our management team has over 230 years of experience to draw on. At Wolkerstorfer, we pride ourselves in our vertically integrated approach offering, testing, plating and painting all under one roof.

Feel free to contact us to discuss your specific requirements and take advantage of our knowledge base to address your most demanding conditions.

The “Wolkerstorfer Way” – Exceptional quality with responsive lead times.

Note to consumers: Wolkerstorfer Company provides metal finishing services to the industrial and commercial marketplace. We do not offer painting or plating services for consumer and household items such as: automobile parts, motorcycle parts, jewelry, kitchen/bath fixtures and furniture. Thank You.